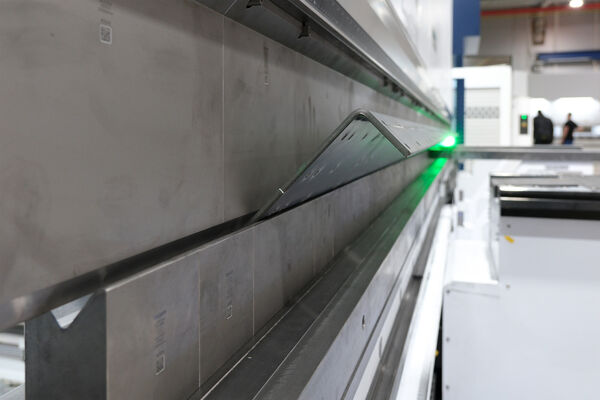

TRUMPF TruBend 81000

The TRUMPF TruBend 81000 is a new generation of flexible large-format bending press machine. It is characterized by its versatility, a usable open height of up to 875 mm, large throat depth up to 620 mm and a max press force of 10,000 kN. Using this device, we can process large and heavy parts up to a length of 8050 mm.

Comprehensive equipment as lower tool displacement, CNC-controlled crowning, laser controlled bending and a 5-axis backgauge, ensures high precision even on complex parts.

The hydraulic clamping of the upper and lower tools and the high speeds of movement in the individual axes also contribute significantly to increasing the efficiency of the entire bending process.

Parameters

|

Press force |

10 000 kN |

|

Bending length |

8050 mm |

|

Width between columns |

7050 mm |

|

Max. table / press beam distance |

1070 mm |

|

Press beam inclined position |

± 10 mm |

|

Throat depth |

620 mm |

|

Usable open height |

875 mm |

|

Y axis press operation speed |

8 mm/s |

|

Y axis rapid traverse speed |

100 mm/s |

|

X axis speed |

800 mm/s |

|

R axis speed |

140 mm/s |

|

Z axis speed |

800 mm/s |

|

Y axis precision |

0,01 mm |

|

X axis precision |

0,02 mm |

|

R axis precision |

0,05 mm |

|

Y axis stroke |

700 mm |

|

Dimensions of the device (l x w x h) |

9280 x 3520 x 5050 mm |

|

Weight of the device |

120 000 kg |